Share

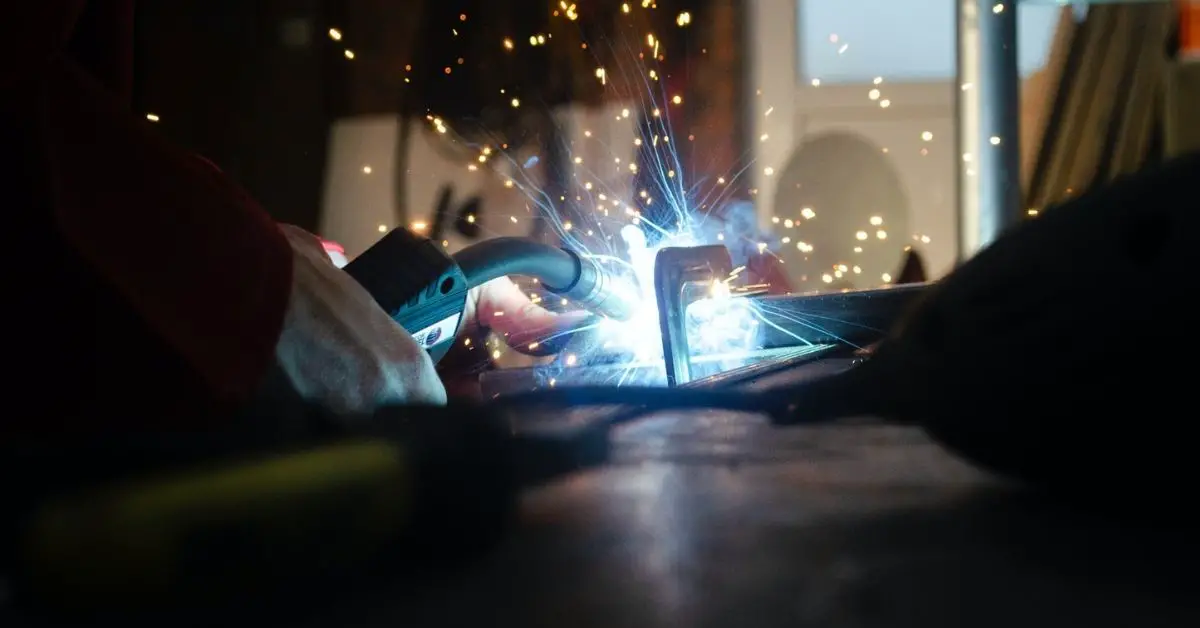

Welding is an important process in the manufacturing industry, but it can be difficult to determine how long it will take for a weld to cool. This article will outline five factors that affect cooling time and provide advice on what you should do if your weld needs to be cooled faster.

How Long Does It Take For A Weld To Cool

The cooling time depends on several factors and also varies from one type of welding to another. Here are five factors that affect the length of cooling time after a weld is made:

The Type Of Metal And The Grade (thickness)

The type of metal you are welding has a large impact on the cooling time after making a weld. The thickness of the metal also matters because thicker metals will take longer to cool than thin ones.

The Welding Equipment Used

Welders use several equipment types that determine how fast or slow it can create and maintain ideal temperatures for welding. For example, TIG (inert tungsten gas) torches offer more control over heat output compared with oxyacetylene torch heads which produce higher volume flames at hotter temperatures in shorter amounts of time.

Temperature And Access To Airflow/Radiation

In order to know how long does it takes for a weld to cool down, one needs to consider both the surrounding temperature well as access to airflow and radiation.

Oxyacetylene torches and MIG (inert metal gas) welders require both airflow and radiation. Otherwise the metal will take a much longer time to cool down compared with TIG or stick welding equipment that does not need as much cooling because it emits less heat during use.

The Type Of Welding Process Used

Lastly, different types of welding processes have varying speeds at which they produce enough heat to create a solid bond between two pieces of metals.

For example, TIG is known for its precise control over electron flow used in heating up the metal while making a weld, whereas oxyacetylene torches are often capable of reaching higher temperatures but lack precision when trying to focus on specific areas along the joint line.

The whole process ends up taking longer with oxyacetylene torches.

The Metals Being Welded Together

Lastly, the type of metals you use for welding together will determine how long it takes to cool down after a weld is made.

For example, aluminum tends to be much more difficult than steel or stainless steel when trying to make a solid bond between two pieces because there can oftentimes still be an oxide film deposited on its surface that prevents heat from conducting and reaching the base material molecules at equal rates during heating up and cooling off due to its high thermal conductivity (how quickly it transfers heat).

This results in different parts along the joint line dropping their temperature at significantly different speeds which interrupts proper fusing unless they are heated again and allowed time enough for them both to cool down in an even and predictable fashion.

What Should You Do If Your Weld Needs To Be Cooled Faster?

Here are the few tips that you should keep in mind if your weld needs to be cooled down faster:

Use a TIG Welder

If possible, use an inert tungsten gas (TIG) welder which is often times the most precise of all welding equipment types. This allows for greater control over heat output and focused cooling on specific areas along the joint line. Use A Smaller Torch Head

Try using smaller torch heads that are more powerful compared with larger ones because they can reach higher temperatures at shorter amounts of time even without having access to airflow or radiation needed by oxyacetylene torches.

The smallest tip size available is usually ideal when trying to maintain precision while heating up small sections along the joint line effectively enough before moving onto other parts later on.

Use The Right Kind Of Gas

Use a gas that is better suited for welding to help cool down the metal when finished making your welds such as helium, argon, or carbon dioxide.

Oxygen tends to create much more oxidation on metals which slows its cooling rate and can sometimes deposit an oxide film in certain areas along the joint line where it’s not desirable especially if you’re trying to achieve a smooth finish between two pieces of metal.

Limit Your Welding Time

Limit how long you spend actually making a weld by using shorter arc lengths instead of longer ones. This allows each section time enough to properly heat up before moving onto other parts after finishing one part off completely first.

Adjust Your Travel Speed

Adjust your travel speed along the joint line as you go depending on how quickly parts are cooling down.

For example, parts that cool off faster need less time for them to be heated up again and vice versa compared with those that take longer before they’re able to reach a temperature high enough where it’s possible to make a solid bond between two pieces of metal together.

Use A Smaller Amperage Setting

If using an AC welder (alternating current), try setting your amperage at lower amounts so long as maintain proper heat output needed by TIG welders instead.

This allows each section more time than necessary in order to slow down your overall welding speed while making sure all areas get heated up evenly without interruptions or gaps. This also lessens oxidation of the metal for better-finished results.

Don’t Aim Your Torch Directly At The Joint

Do not aim your torch directly at the joint line because this tends to overheat specific areas more than others, especially if you’re using a TIG welder where it’s much easier to lose control over heat output without realizing it which can lead to blow-through or other issues along the joint line that are difficult or impossible to fix later on.

Instead, try moving your torch in slow sweeping motions while holding its tip close enough so as long as possible before reaching parts that need less time for them to be heated up again after finishing one off first.

Use A Dull Red Glow For Preheating

If preheating the entire joint line, try using a dull red glow instead of bright blue or white to help ensure each part melts together evenly without air gaps being created by parts that have been overheated.

This makes it easier for you to achieve proper penetration and fusion between two pieces of metal where they meet up along the joint lines so long as maintaining even heat distribution throughout the entire process is achieved from start to finish which means less time needed overall in order to make your weld successfully.

With these tips kept in mind, hopefully, this helps you understand how important cooling times can be when making a successful weld.

If working with delicate material types such as aluminum because it’s far more vulnerable than steel when exposed to excessive amounts of heat over short periods at a time which can cause problems with the finished product. You may also want to read our articles about keeping your welding table from rusting and how you can weld a rusty metal.

0 Comments