Share

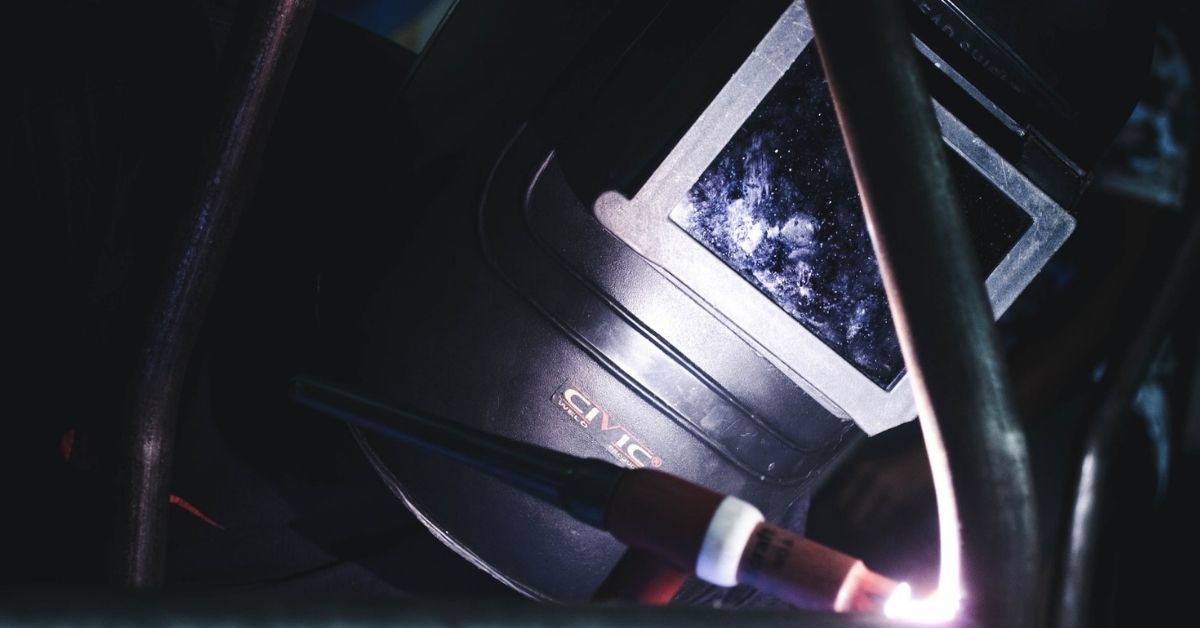

Leather offers some additional protection that will keep you better protected when working in harsher conditions like these! This blog post will show you how to add leather to the welding hood for added safety!

Welding can be hazardous to your health. The smoke, the fumes, and the heat are all bad for you. To help protect yourself with a welding hood is always recommended, but it doesn’t offer much protection from skin contact with harmful substances.

Why People Are Adding Leather to Their Hoods

Protecting Skin From Burns

The primary reason people add leather is to protect their skin from burns. The material, typically cowhide or goatskin, will not melt like Nomex and melton wool when it’s exposed to an open flame.

For this reason, leather can provide some degree of protection against flash fires while welding on an extremely hot piece of metal.

Of course, leather is not completely flame-resistant and some damage can occur when exposed to extreme heat for an extended period of time. But if you are new to welding or only do it on occasion, this will give you a bit more protection than just wearing wool clothing alone.

A thick cowhide hood should be able to handle most welding jobs without causing any skin damage.

Adding Style to Your Helmet

Another benefit associated with leather welding hoods is their aesthetic appeal. While the most common color is black, some people like to wear brown or tan-colored clothes during certain seasons of the year.

For this reason, many welder’s fashions an alternative style by adding dark brown goatskin around the face area for a unique look.

Just make sure that you avoid buying light brown material because it will not be as effective at blocking out ultraviolet rays from entering your helmet and potentially burning your eyes. If you need full protection all day long, stick with darker colors instead of lighter ones.

How To Add Leather To The Welding Hood For Protection

Step 1: Prep the Material

The first step in adding leather to your welding hood is prepping the material. For starters, make sure you always buy new products and never recycle old clothes for this project because they might not be flame resistant any longer.

You also need to remember that although some types of leather are more durable than others, all materials will eventually wear out over time so try not to get attached if it does start to show signs of damage while working on a hot piece of metal.

Finally, pick up an industrial sewing machine or hand stitching kit at your local hardware store before attempting this job because it’s quite difficult without them! If you do choose the latter method though, just follow our guide below closely for best results.

Step 2: Trace Your Helmet

Once you have all the necessary tools, it’s time to trace your helmet. You can use a regular marker or pen for this step and make sure that you cover any plastic areas completely with drawings before moving on because the leather will not stick if there is an existing layer of material underneath!

If you want to add some extra protection though, cut out strips from another piece of cowhide and wrap them around the headgear beforehand to protect against scratches as well. In most cases, one thin strip placed vertically across the top should be sufficient enough depending on how often you weld.

Step 3: Cut Out Your Pattern

After tracing your helmet onto a new piece of leather using permanent ink or a pen, carefully place it overtop again so you can cut out your pattern.

Make sure that you take a good look around the entire area to make sure there are no rips or holes because they will inevitably show up when you wear them and become an eyesore!

Just remember, small cuts here and there won’t be visible from far away so don’t worry too much about being perfect for this step in particular.

Step 4: Sew It Together

Now all you have left is sewing everything together using either hand stitching or your industrial machine depending on which one was easier to get hold of at the hardware store earlier.

For some welder’s with limited resources though, this might not be feasible without borrowing someone else’s equipment first (if possible). In most cases, threading a needle with thick thread is difficult enough on its own, never mind sewing it into a pair of leather pants!

Step 5: Trim the Edges

Finally, once you are done stitching everything together, all left to do is trim off any excess material using either some scissors or an industrial paper trimmer.

This step isn’t necessary but can make your welding hood look more professional in some instances, depending on how much space there was between each stitch.

If anything though, this part should take less than five minutes, so don’t worry too much about doing it perfectly since no one will be able to tell anyway when you’re wearing full protective gear at work!

Conclusion

Now that you know how to add leather to your welding hood for protection, it’s time to try the process out in real life.

Just remember, when it comes to working with hot metal or just about anything else around an open flame, slow and steady wins the race every time! You can also check our post about removing welding spatter from glass and changing welding helmet lenses.

0 Comments