Share

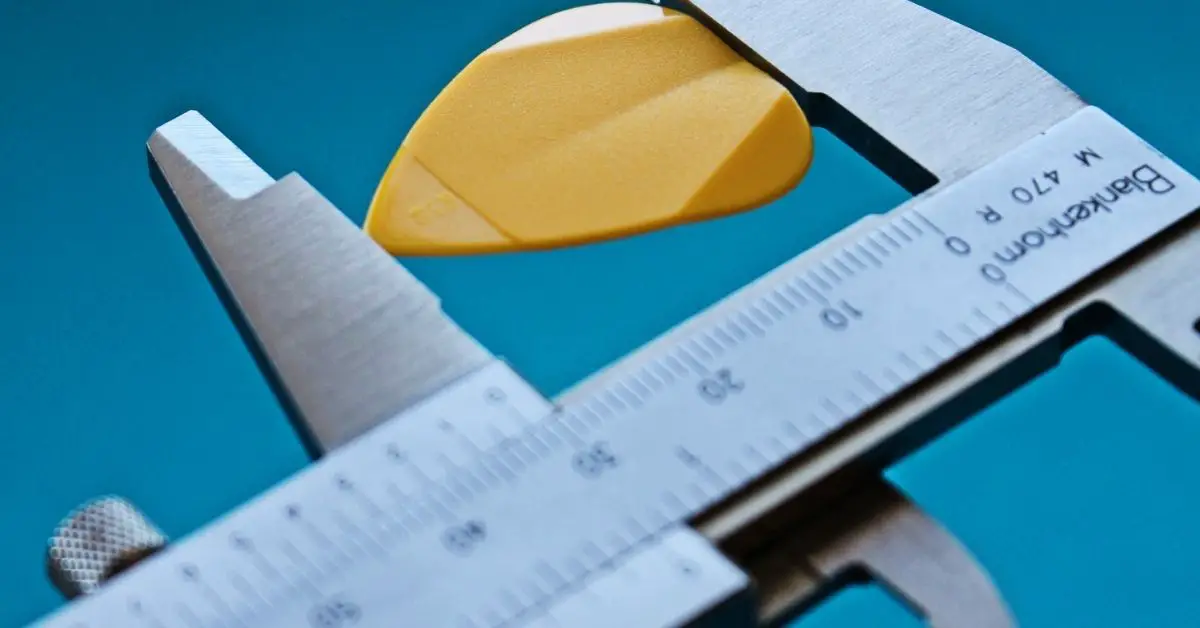

In this blog, we are going to show you how to measure a drill bit with calipers. Many people assume that you can only use a caliper to measure the thickness of something round. As it turns out, you can measure other things as well!

How to Measure a Drill Bit with Calipers

Calipers are not difficult to use. They are a tool that can be used in many different professions. Calibers come in all sorts of shapes and sizes depending on what you plan on using them for; circular or linear measurements are the two most common types. Here, we will go over how they’re best used for measuring drill bits with calipers.

1) Measure the length of the drill bit

This step is crucial because it determines how thick your calipers should be for accurate readings. If you measure a long drill bit (e.g., over 12 inches), use two sets of calipers on either end of the measurement for accuracy and consistency among measurements.

2) Measure the outside diameter of the drill bit

The next step is to measure the circumference or “outside diameter” of your drill bit. This will be used for comparison when measuring inside diameters and thicknesses, so getting an accurate number is important.

3) Measure drill bit inside diameters

Now that you have the length and circumference of your drill bit, it’s time to measure its thicknesses. To do this, you can use calipers for inside diameters or “thicknesses” of your drill bit. These measurements will be used to determine the volume and mass of your material as well as how long it takes a drill bit to pass through that diameter depending on its speed and RPMs (revolutions per minute).

4) Calculate drill bit volume

Depending on what you’re using your drill for, there are various formulas to use that will determine how long it takes a drill bit to pass through one area of a material. For example, suppose the circumference has been measured and is used in conjunction with the inside diameter measurements taken earlier. In that case, its length can be calculated by plugging those numbers into a drill volume equation.

5) Calculate drill bit mass

If you’re looking for more precise measurement and calculation of the weight, then the volume isn’t going to be enough. Calipers can also be used to measure the density of the material by measuring its mass and thicknesses with calipers. This is an advanced use that requires some math skills like converting units from grams to ounces, but it can be useful if you need more accurate measurements.

6) Calculate drill bit RPMs

This step is only necessary if you’re using them for drilling purposes. Similar to the volume equation, there are also equations for determining how many revolutions per minute your drill will make when it passes through the material with a certain circumference or length.

This can be useful because different types of materials have different recommended speeds that should be used when drilling. This is a great way to ensure that you’re using the proper RPMs for whatever material you drill through, especially if it’s something particularly tough like concrete or steel.

Now that you know how to use calipers for measuring drill bits, you can determine the thickness of length. We hope that this blog has been helpful. We also recommend checking out our post about how to remove broken drill bits from aluminum and how to extract broken drill bits.

0 Comments